Natural gas cogeneration

- Home

- Natural gas cogeneration

The ideal solution for the efficiency of energy-intensive structures.

Suitable for many industrial, tertiary and service sectors, cogeneration responds effectively to the needs of energy-intensive realities, characterized by high consumption of heat and electricity.

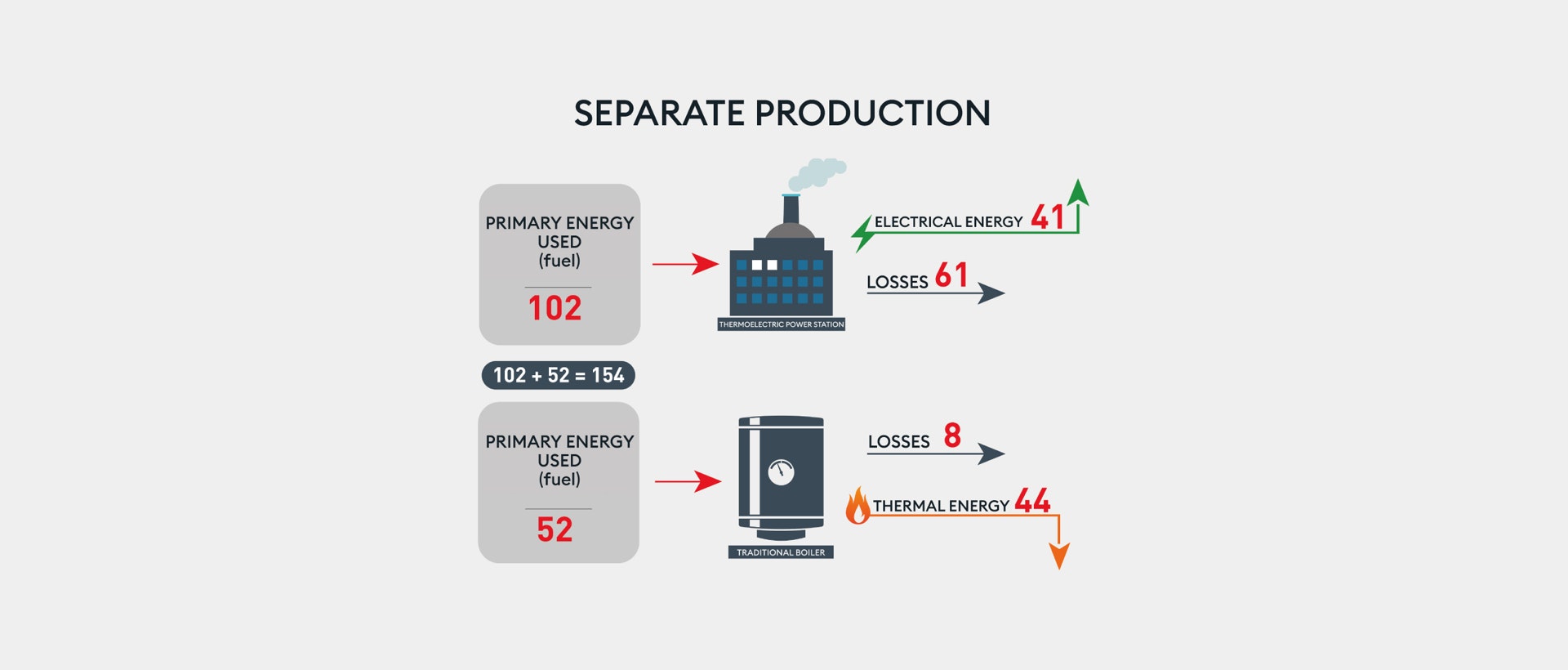

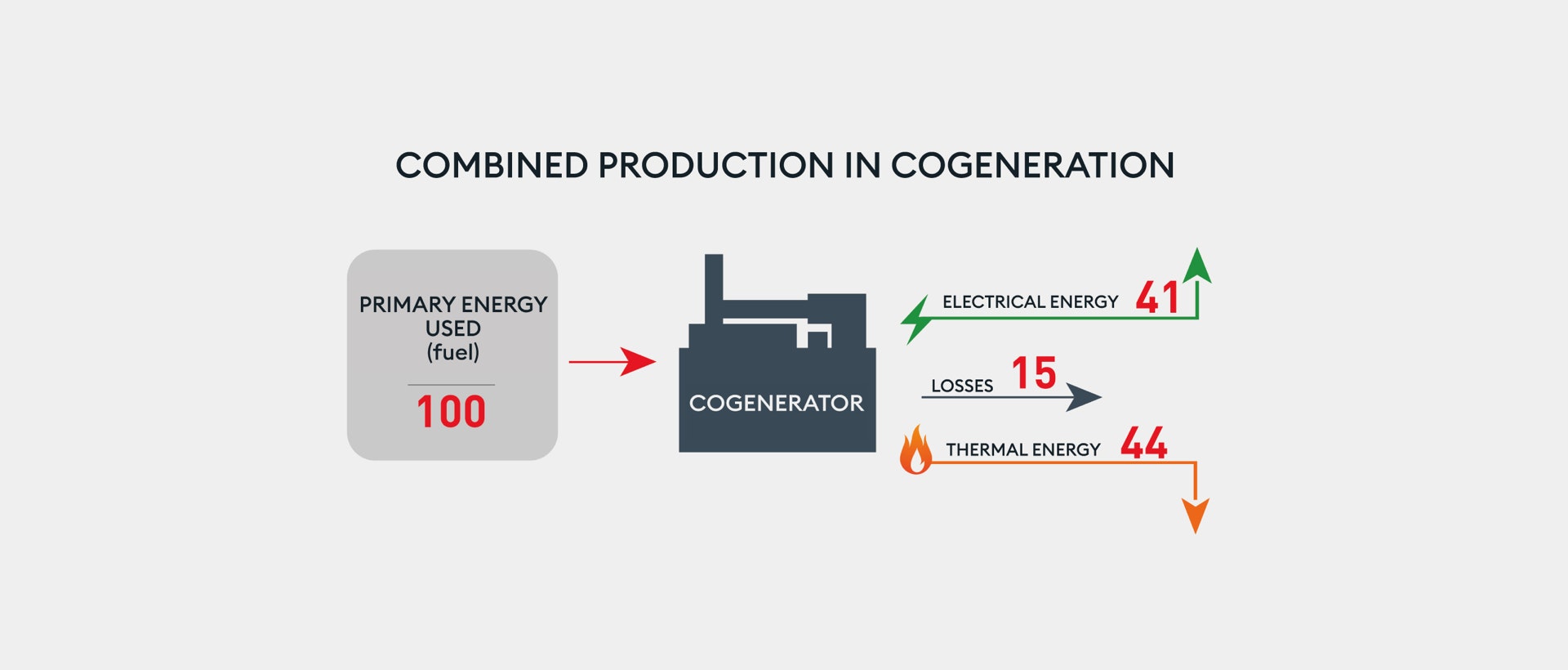

In fact, a cogeneration plant simultaneously produces electricity and thermal energy from a single energy source inside an integrated system. This is why we use the phrase combined heat and power.

Therefore, using the same fuel (natural gas) to generate two energy carriers (electricity and heat) makes it possible to increase the effective use of the source fuel up to 85%, with the resulting reduction in energy costs and CO₂ emissions, compared to the separate production of electricity and heat.

The use of the heat generated during the process, which would otherwise be lost, allows cogeneration to obtain the highest levels of energy efficiency and performance, with the advantage of being able to manage energy production continuously, reliably and safely.

Products

How a cogenerator works

A cogeneration plant consists of an Otto cycle engine, powered, in this case, by natural gas, which produces mechanical energy that is conveyed through an alternator to generate low voltage electricity, which is then transformed into medium voltage electricity.

Heat recovery takes place on two fronts:

from the engine cooling water, using a plate-type heat exchanger that allows obtaining high-temperature water;

from the flue gas fumes, which, being close to 400°, can be used to produce hot water, superheated water, steam or diathermic oil through a boiler, or be used pure in the process.

Energy produced

Electric power

to be sold to the network

Thermal energy

for the production of:

hot water

superheated water

steam

diathermic oil

cold water (CCHP)

Technologies and operating process of a cogenerator

Sectors of application

Airports

Ceramic and brickwork industry

Chemical and pharmaceutical industry

Data processing centers

Engineering companies

Food & Beverage Industry

Greenhouse

Hospitals

Hotels

Paper mills

Plastic industry

Textile industry

Shopping centers

Universities