Cogeneration from special gases for the production of electrical and thermal energy.

AB becomes the reference point for cogeneration plants from special gases, which use gas recovered during oil extraction and in coal processing processes.

In oil wells, ECOMAX® allows the safe treatment of associated petroleum gas or APG, mainly composed of methane, which escapes under pressure during mining activities and which is often flared in order to avoid explosion hazards.

With cogeneration it is possible to control and manage it, transforming it into an opportunity: it is exploited as a fuel for cogeneration plants powered by gases generated by oil production, which in turn produce electricity and heat and allow a reduction in energy costs.

Coke oven gas, an abundant by-product of converting coal to coke for steelmaking, is also suitable as a fuel for ECOMAX®.

In coal mines, ECOMAX® makes it possible to exploit methane, present both as a free gas and as a gas absorbed on the internal surface of the carboniferous rock and surrounding rocks.

With the ECOMAX® solutions powered by special gases, both the heat and the electricity produced can be used for the needs of the mining sites. Excess electricity, on the other hand, can be sold to the network.

ECOMAX® cogeneration plants can also be fed with syngas, or synthesis gas, a gaseous mixture artificially produced from substances that contain carbon, such as agricultural waste or by-products from the forestry industry.

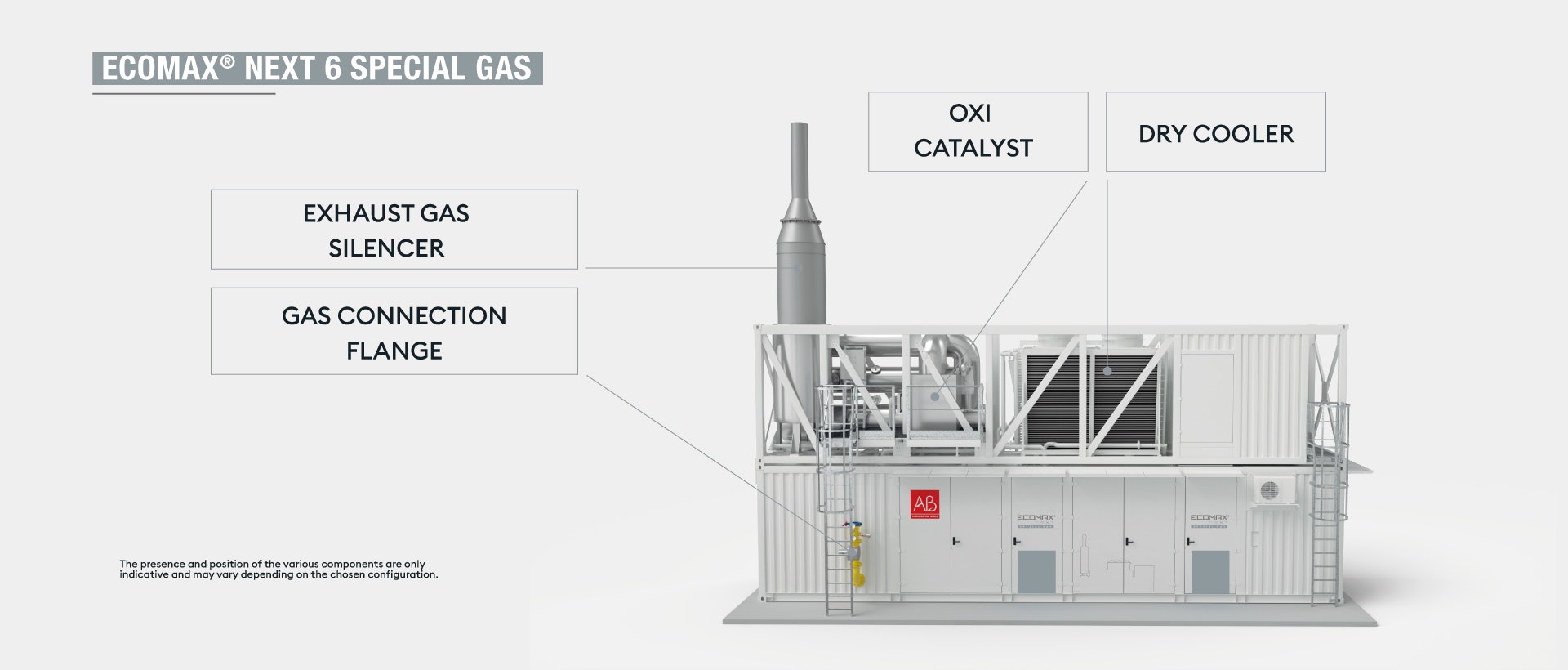

ECOMAX NEXT® Special Gas

Easy configuration, which meets the needs of all markets

Ease of transport and installation

Time and risk optimization in the installation and commissioning phase

Interconnection with existing plant systems

Availability of service assistance even in difficult situations

Customised solutions

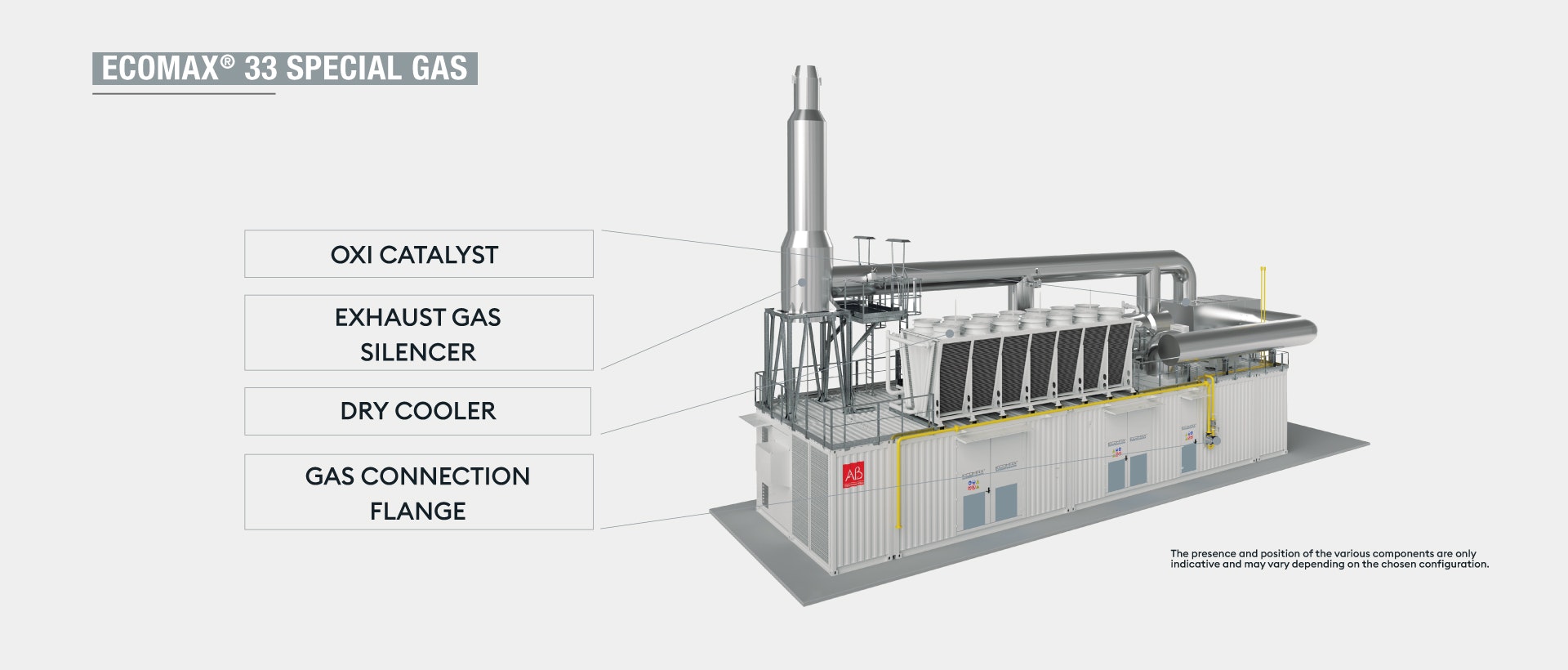

The ECOMAX® solutions powered by the special gases described above, must be studied and customised on a case-by-case basis after the customer has supplied an analysis of the gas used.

Solutions

Industry

Leaflets

ECOMAX® Catalog